Fermentation Monitor Makes Brewing Easier

Endress+Hauser, a global leader in measurement and automation technology for process and laboratory applications, offers its QWX43, a fermentation monitor that continuously measures all parameters relevant to the fermentation process and allows for transparency in fermentation processes, for example in beer.

Some of the benefits of using it include:

- Precise and repeatable measurements replace manual sampling and laboratory analysis,

- Minute-by-minute update of the crucial process parameters, where the results can be retrieved at any time and from anywhere,

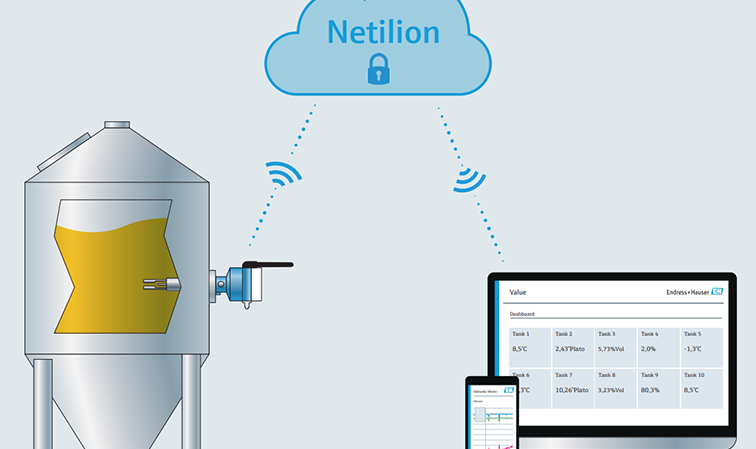

- Automatic creation, saving and downloading of batches and values in Endress+Hauser’s IIoT ecosystem, Netilion,

- Data-driven process improvements visualised in a control system or web-based application,

- Simple tank-integrated cleaning.

The monitor is a measuring device that supports brewers in their work and continuously screens all parameters that are important for the fermentation process of beer. The multi-sensor system provides precisely measured values that can be retrieved at any time and from anywhere.

For a stable brewing process, it is important to keep an eye on numerous parameters during fermentation. For example, to determine the residual extract, reference measurements are made once or twice a day at each fermentation tank using a beer spindle, refractometer or other laboratory equipment. This can take 10 to 15 minutes per tank, including sample preparation.

In addition, the infrequent measurements only allow selective results. The end of the fermentation process, or the ideal time for bunging, can only be determined approximately.

The QWX43 fermentation monitor also allows precise measurement in real time and closes these data gaps. It measures the parameters that determine fermentation. The data can be accessed directly via the control system.

This gives brewers full insight into the fermentation process and saves them any further effort. In addition, they can set up alarms and remain informed immediately about critical deviations in the fermentation process.

The device can be easily attached to existing process connections and does not need to be adjusted or calibrated. Commissioning is done in just a few steps, after which the device works by itself.

With just a few clicks of the control system or in the IIoT (Netilion) App, brewers can get updated on the current status of the fermentation cellar. This enables quick intervention, safe control and optimisation, if necessary.

Cleaning is also easy, thanks to the fully hygienic sensor design. The device can always remain in the tank and does not need to be taken out for cleaning.

Endress+Hauser specialises in measurement instrumentation, services and solutions for industrial process engineering and provides process solutions for flow, level, pressure, analytics, temperature, recording and digital communications, optimising processes in terms of economic efficiency, safety and environmental impact.

Users come from various industries, and include, among others, food and beverage, water and waste water. For further queries, write to loganathan.subramanian@endress.com.

Source: Brews and Spirits Magazine

https://brewsnspirits.in/fermentation-monitor-makes-brewing-easier

Please feel free to contact us. We will get back to you within 2 business days.